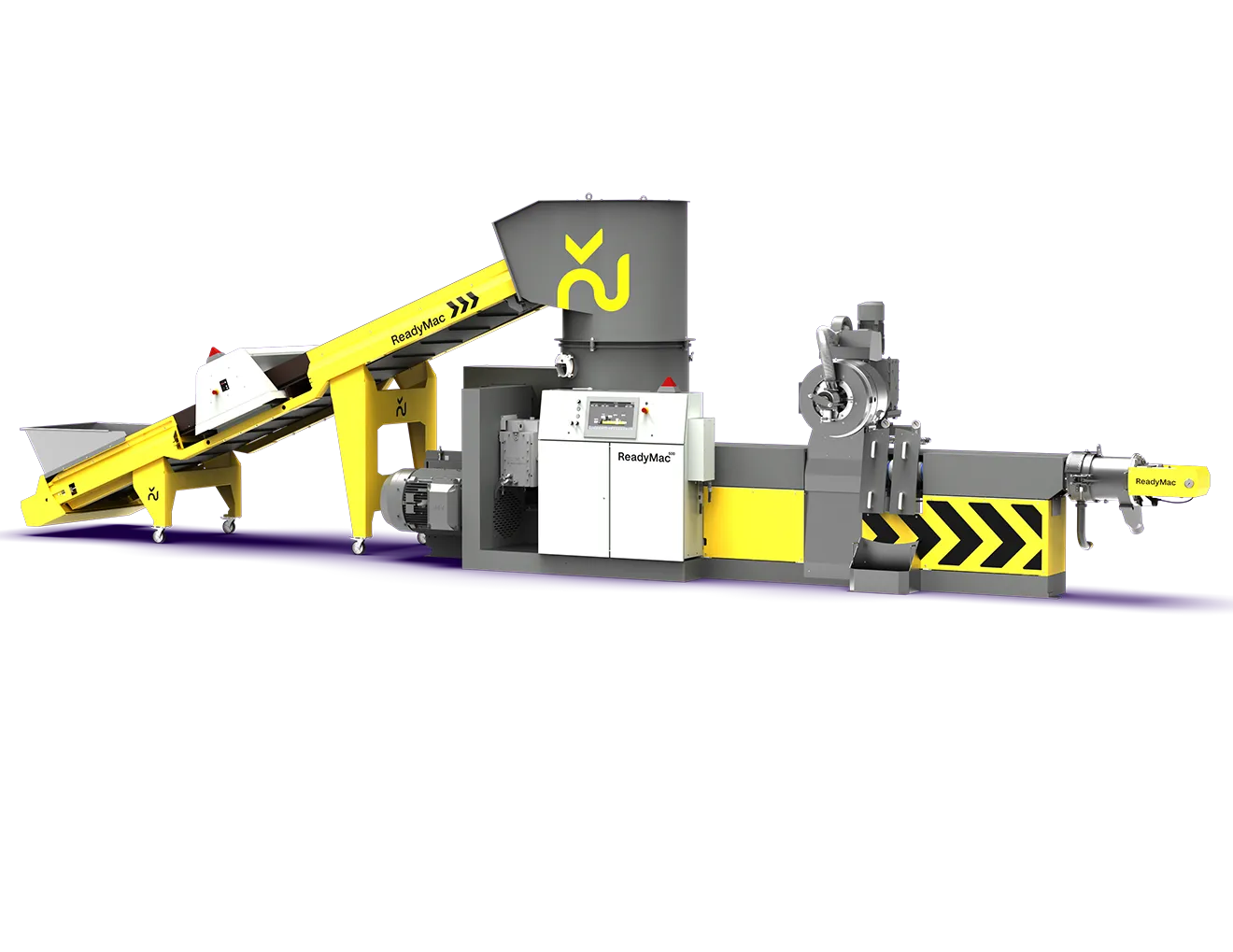

ReadyMac500

The high-quality plastic recycling machine.

Top brand quality at a low fixed price.

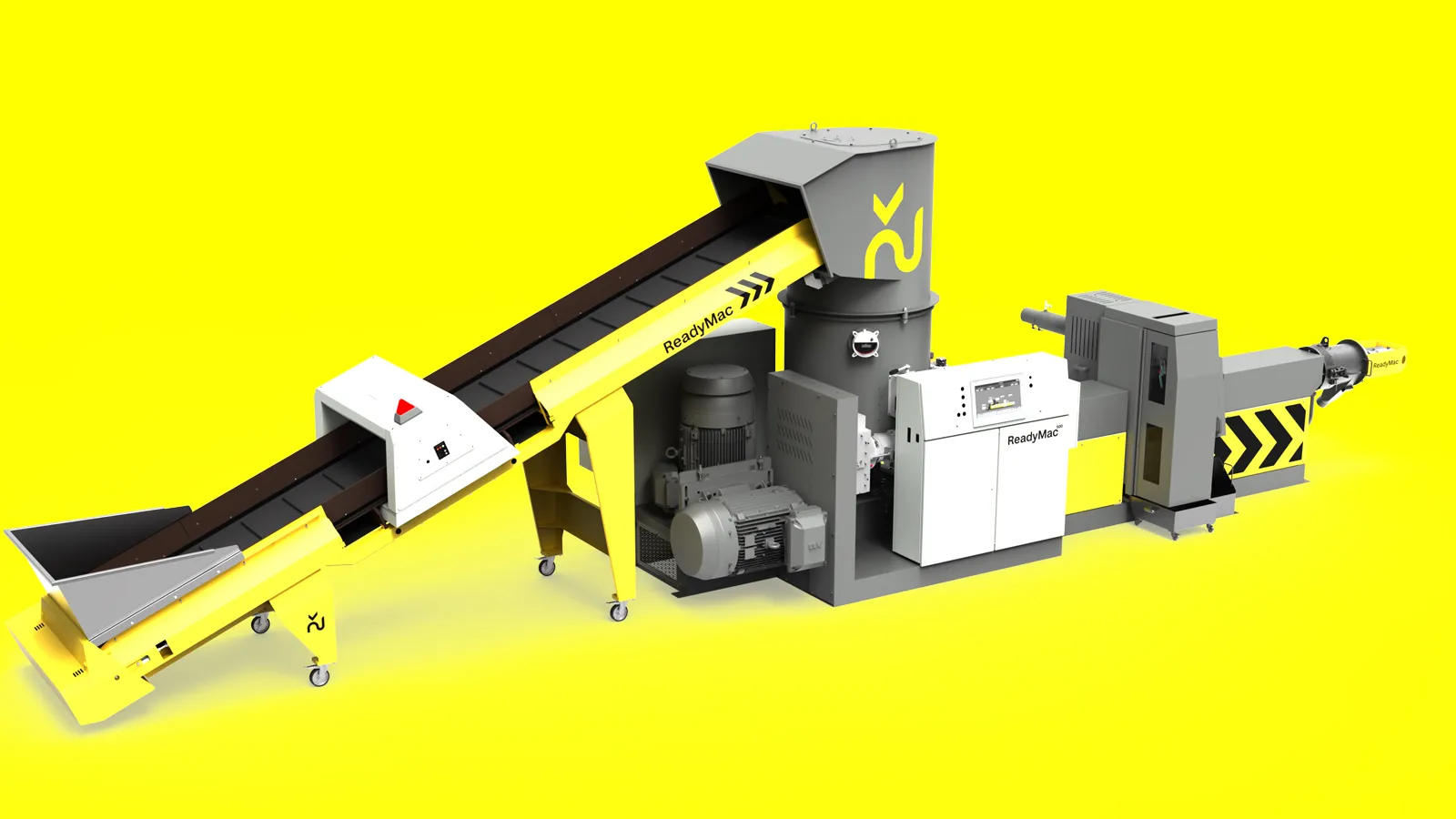

ReadyMac500 HD

The high-quality plastic recycling machine

for heavily contaminated material.

Our ReadyMac is a universal plastic recycling machine for sale in a standardized design. The standardized design means we always have a large number in stock.

It processes film, flakes and regrind material from PE, PP, PS, PC, PA 6.0. to make high-quality recycled pellets. This makes the machine suitable for various applications - from post-consumer to post-industrial and in-house.

The ReadyMac is immediately available. You can keep material flowing without long and costly stockpiling. This way, you can continue to supply your customers quickly and reliably.

An important factor: Spare parts availability! They are dispatched immediately by the EREMA after sales team. Spare parts are always in stock and sent quickly to your site.

This patented technology has been in use at EREMA for many years. It ensures consistently reliable quality of the recycled pellets without compromise.

Download all the important documents for your new plastics recycling machine now! Our download package includes:

ReadyMac 500 – Download Package

ReadyMac 500 HD – Download Package

We would be happy to put you in touch with competent and reliable financing partners to assist you with the financing of your plastic recycling machine.

We would be pleased to help you free of charge and without obligation.

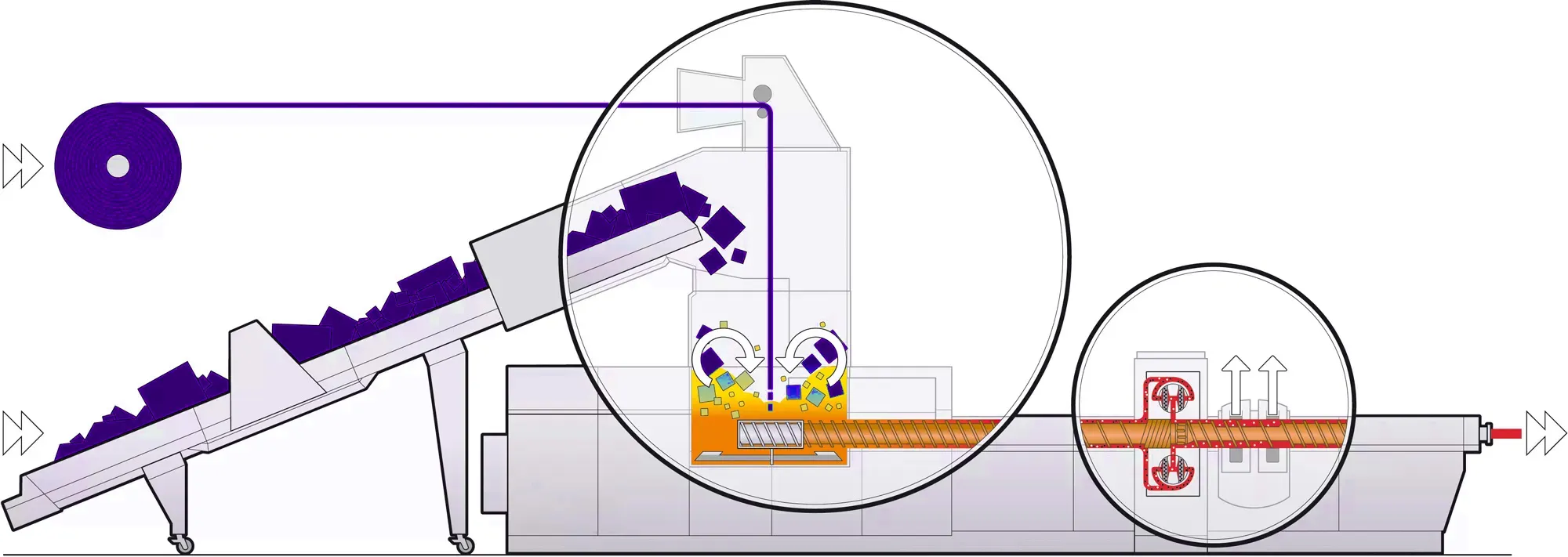

Thanks to EREMA's patented extruder system, even materials that are difficult to process can be recycled effortlessly. These include printed film and wet materials.

They undergo

The groundbreaking key principle of TVE technology is that melt filtration is carried out before extruder degassing. This is because impurities can be removed more efficiently. That is how you achieve the highest quality end products.

The ReadyMac 500 and ReadyMac 500 HD have two different filter systems that make them unique.

| ReadyMac 500 SW/RTF melt filter | ReadyMac 500 HD EREMA laser filter |

| Automatic partial area backflush with high cleaning efficiency | High-performance filter for continuous contaminant discharge |

| Large active total screen surface area | High throughputs even with high degrees of contamination |

| High level of automation | Permanent screen cleaning |

| Robust | Constant pressure operation for high process stability |

| Minimum melt loss through thickening up to 50% |

Do you have questions about the advantages of our ReadyMac plastic recycling machine, which is for sale and immediately availabl?

Our experienced team would be pleased to help you at any time.

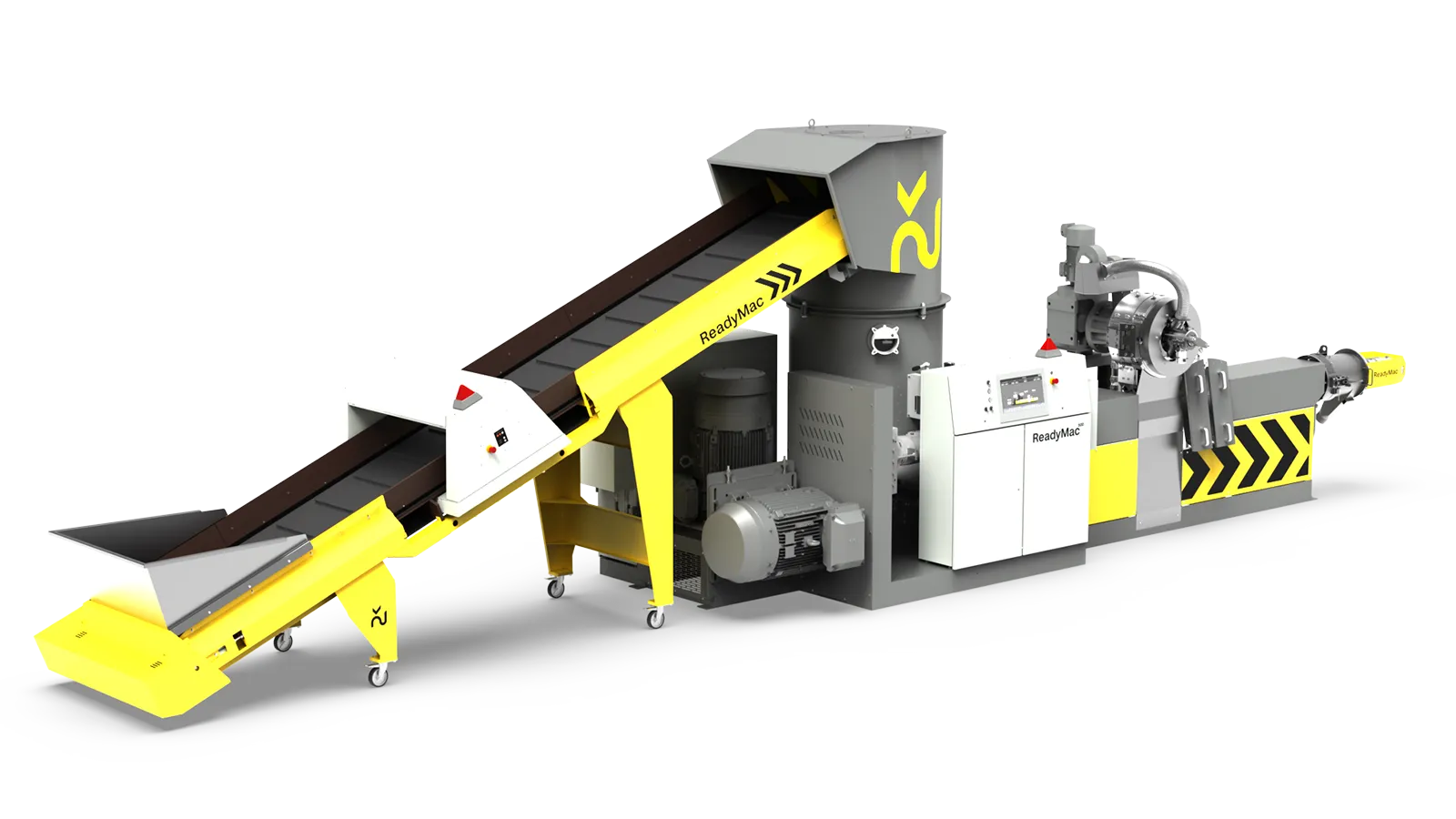

Conventional plastic recycling machines are often limited to processing a specific material. In contrast, the ReadyMac covers a wide range of materials. Frequent retooling or additional and expensive special equipment are not needed.

This is made possible by the innovative multipurpose screw. It shreds PE, PP, PS, PC and PA 6.0 efficiently and reliably. No matter whether these are contaminated or heavily printed:

This impressive versatility means the ReadyMac sets new standards for a more sustainable future.

From post-consumer to post-industrial and in-house, our plastic recycling machine for sale effortlessly meets the challenges of a wide range of applications.

It reliably processes films, pre-shredded film flakes, regrind and other forms of material. The ReadyMac can repelletize the following materials:

„Thanks to the smooth collaboration and technical preparation, commissioning and training were quick and uncomplicated. The result: 24-hour operation was already possible on the 3rd day - and with a higher output quantity than agreed in advance! This means that nothing stands in the way of recycling our HDPE Regrind material into first-class pellets.”

- Cersa, Ecuador

We know that financing a plastic recycling machine is an important decision. That is why we are here to help and advise you. We will assist you in finding the right finance partners.

We can buy back your old machine and take care of dismantling and transport. This means that we ensure a short and virtually seamless transition to the commissioning of your new ReadyMac - with no production downtime. Our experts can handle the whole process.

When it comes to commissioning the machine, we take care of it personally. That is how we can ensure that your plastic recycling machine works optimally. You can put all your energy into focusing on your sustainable success.

We support you beyond the purchase of your new machine. With technical support from EREMA, one of the leading experts in the plastics industry, you always have a competent team ready to help you out.

Our local EREMA service technicians are always available with their know-how.

Output per material type:

*) all output rates quoted are examples that depend on the actual material properties (such as residual moisture, printed, degree of contamination, MFI, etc.) as well as the fineness of filtration.